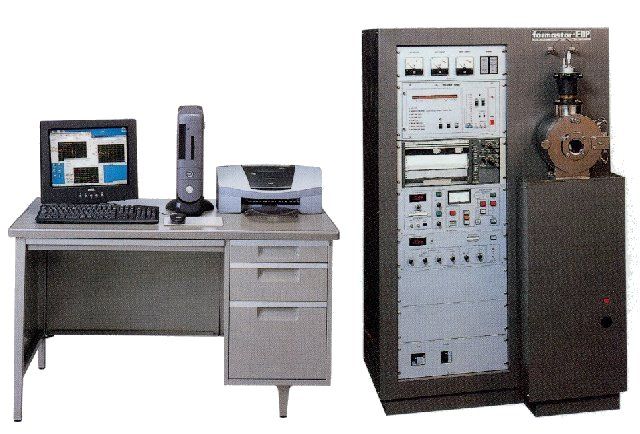

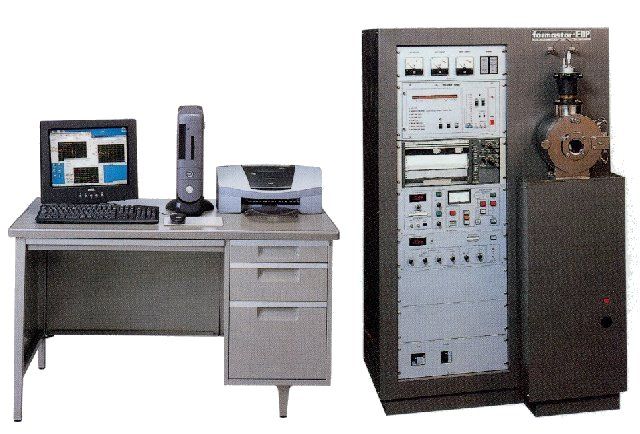

A specimen in dia.=3

x L=10 mm with thermocouple dia.=0.2R

welded on one side is inserted into a quartz

tube and a quartz rod is set as shown in the

drawing. The specimen is heated in radio

frequency induction coils and cooled by

cooling media sprayed through nozzles on

inner coil by grasping thermal dilation by

differential transformer during the process,

transformation of metallic structure of iron

and steel and also thermal treatment

characteristics can be measured / recorded.

Temperatures, dilation quantity and time

data memorized in the data logger are read

out and automatically operated / analyzed =

transformation temperature detected so that

CCT / TTT curves are obtained.

|

|

* Heating Rate

|

100 deg.C / sec.

|

|

* Cooling Rate

|

300 deg.C / sec.

( He: 900 to 400 deg.C ) |

|

* Dilation Range

|

50, 100, 250, 500 micro-m /FS

|

|